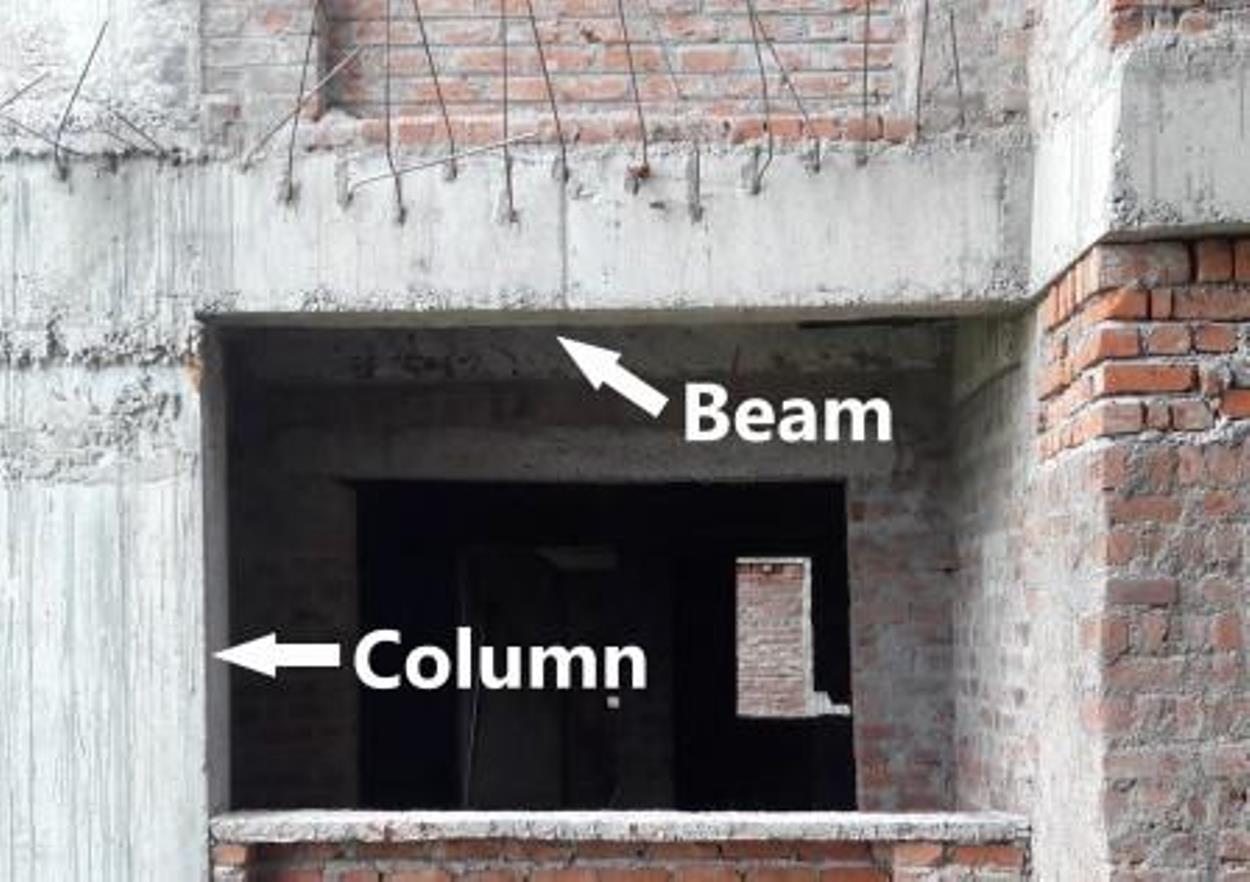

Tips for Design of RCC Concrete Beams

If you are new to the design of RCC Concrete beams or any structural members you might find it difficult because what we learn from books during civil engineering studies is different from what is practiced in the construction field. You shouldn’t worry “that” much because both analyzing and designing of structural members is easy once you understand industrial practices and get some experience. Here I am going to give a few tips for the design of RCC Concrete Beams.

Tips for Design of Size, Shape, and Span of RCC Beams

- Keep the width of the beam minimum. Some commonly used beam widths are 200, 230, and 300 for practical, structural, and aesthetic reasons.

- For plinth, beams assume overall depth from span/15 to span/18

- For Tie, beams assume overall depth from span/18 to span/20

- For Floor, beams assume overall depth from span/12 to span/15

- Design RCC Concrete beam section based on the maximum moment and shear force.

- Mu/bd^2 can go up to 6 in case of the heavy beam with long span

Tips for Steel Reinforcement Design of RCC Beams

- Use smaller sized bars for good efficiency.

- For simply supported beam at least 1/3 of positive reinforcement should extent along the same face of the member into support to the length equal to Ld/3

- In case of the continuous beam at least 1/4 of positive reinforcement should extend along the same face of the member into support to the length equal to Ld/3

- The maximum spacing of stirrups shall be 0.75 times the effective depth so restrict the spacing of the stirrups to 225mm. (300*0.75=225)

- Curtailment length shall be checked with the development length

- When using two lines of reinforcement keep the larger diameter bars on the outer layer for maximum efficiency

- Provide hanger bars at the intersection of Main and Secondary beam for a cushion.

- Check the torsion of the main beam when the secondary beam rests on it.

- Increase the reinforcement in the support and increase the developmental length by 25% in case of the cantilever

- Learn to use T-Beam and L-beam design instead of Rectangular RCC concrete beam, if possible, for maximum design and cost efficiency and to avoid compression reinforcement.

Quality metal buildings will retain their original beauty and value outstandingly well.

ReplyDelete4 Things that Make a Prefab Steel Building Better than Traditional Ones

Thanks for shearing Tips for Steel Reinforcement Design

ReplyDelete