Introduction

Natural or stream sand area unit weather-beaten and exhausted particles of rocks and area unit of varied grades or sizes relying upon the quantity of carrying. Now-a-days sensible sand isn't without delay out there, it's transported from a protracted distance. Those resources are exhausting terribly speedily. thus it's a desire of the time to search out some substitute to natural stream sand.

The artificial sand made by correct machines is a much better substitute to stream sand. The sand should be of correct gradation (it ought to have particles from a hundred and fifty microns to four.75 millimeter in correctproportion).

When fine particles area unit in correct proportion, the sand can have fewer voids. The cement amount needed areless. Such sand are a lot of economical. Demand for factory-made fine aggregates for creating concrete is increasing day by day as stream sand cannot meet the rising demand of construction sector. Natural stream sand takes legionyears to make and isn't repleneshible.

Because of its restricted provide, the value of Natural stream sand has sky rocketed and its consistent provide can not be secured. beneath this circumstances use of factory-made sand becomes inevitable.

River sand in several components of the country isn't stratified properly and has excessive silt and organic impurities and these is damaging to sturdiness of steel in concrete whereas factory-made sand has no silt or organic impurities

However, many folks in Asian

country have doubts concerning quality of concrete / mortars once factory-made or artificial

sand area unit used. factory-made sand are frequently wont to build quality

concrete for many years in Asian country and abroad.

Pune - Mumbai state highway was fully engineered exploitation artificial/manufactured sand.

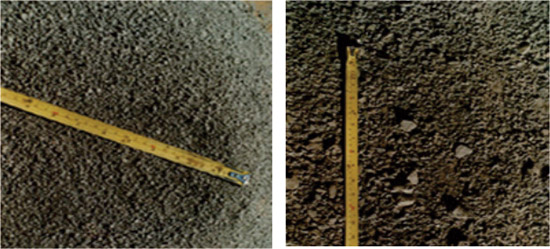

Only, sand manufactured by VSI crusher/Rotopactor is cubical and angular in shape. Sand made by other types of machines is flaky, which is troublesome in working. The Jaw crushers, are generally used for crushing stones in to metal/aggregates. Manufactured sand from jaw crusher, cone crusher, roll crusher often contain higher percentage of dust and have flaky particle.

IS Code Provisions

BIS Guidelines IS: 383-1970 for selection and testing of Coarse and Fine aggregates available. Generally, Sand is classified as Zone I, Zone II, Zone III and Zone IV (i.e. Coarser to Finer). There is sieve designation for each zone. Gradation is made in accord with the usage of the sand. There are testing sieves, consists of 4.75mm, 2.36mm, 1.183mm, 600microns, 300 microns, 150 microns and a pan

Typical Compressive Strength of Concrete: The following results show the behavior of manufactured sand and riverbed sand when used in concrete:

Now-a-days, Vastu Shastra is more popular, consults Vastu by many people while constructing a house. As per Vastu Shastra, the building material must be free from traces of human or animal body. The river sand contains bones of human beings and animals. The shells are also a kind of bone. It is not easy to take out all such things present in the river sand. Hence, the best solution for this is to use artificial/crushed sand of good quality for human well being.

Environmental Impact

The River sand lifting from river bed, impact the environment in many ways:

www.vsicrushers.com

www.robosilicon.com

Natural or stream sand area unit weather-beaten and exhausted particles of rocks and area unit of varied grades or sizes relying upon the quantity of carrying. Now-a-days sensible sand isn't without delay out there, it's transported from a protracted distance. Those resources are exhausting terribly speedily. thus it's a desire of the time to search out some substitute to natural stream sand.

The artificial sand made by correct machines is a much better substitute to stream sand. The sand should be of correct gradation (it ought to have particles from a hundred and fifty microns to four.75 millimeter in correctproportion).

When fine particles area unit in correct proportion, the sand can have fewer voids. The cement amount needed areless. Such sand are a lot of economical. Demand for factory-made fine aggregates for creating concrete is increasing day by day as stream sand cannot meet the rising demand of construction sector. Natural stream sand takes legionyears to make and isn't repleneshible.

Because of its restricted provide, the value of Natural stream sand has sky rocketed and its consistent provide can not be secured. beneath this circumstances use of factory-made sand becomes inevitable.

River sand in several components of the country isn't stratified properly and has excessive silt and organic impurities and these is damaging to sturdiness of steel in concrete whereas factory-made sand has no silt or organic impurities

|

|

|

Manufactured

sand

|

River

sand

|

Pune - Mumbai state highway was fully engineered exploitation artificial/manufactured sand.

Issues with factory-made Sand:

1. The

Civil engineers, Architects, Builders, and Contractors agree that the

watercourse sand, that is on the market these days, is deficient in several

respect. It will content terribly high silt fine particles (as just in case of

Filter sand).

2. Presence

of alternative impurities like coal, bones, shells, mineral and silt etc makes

it inferior for the employment in cement concrete. The decay of those

materials, thanks to weathering result, shortens the lifetime of the concrete.

3. Now-a-days,

the govt. have place ban on lifting sand from watercourse bed.

4. Transportation

of sand damages the roads.

5. Removing

sand from watercourse bed impact the surroundings, as groundwater level goes

deeper & ultimately dry.

General needs of factory-made Sand:

1. All

the sand particles ought to have higher crushing strength.

2. The

surface texture of the particles ought to be swish.

3. The

edges of the particles ought to be grounded.

4. The

quantitative relation of fines below 600 microns in sand mustn't be but

half-hour.

5. There

mustn't be any organic impurities

6. Silt

in sand mustn't be over two, for crushed sand.

7. In

factory-made sand the permissible limit of fines below seventy five microns

shall not exceed 15 August 1945.

8. Crushing,

Screening, and laundry

| Rotopactor( Sand Making machine) | Vertical Shaft Impactor |

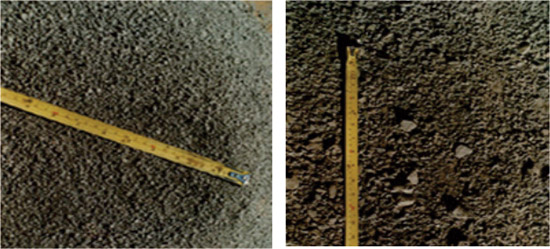

Manufacturing of Sand process involves three stages, crushing of stones in to aggregates by VSI, then fed to Rotopactor to crush aggregates into sand to required grain sizes (as fines). Screening is done to eliminate dust particles and Washing of sand eliminates very fine particles present within. The end product will satisfy all the requirements of IS:383 and can be used in Concrete & construction. The VSI Plants are available capacity up-to 400Ton Per Hour(TPH). manufactured Sand (M Sand):

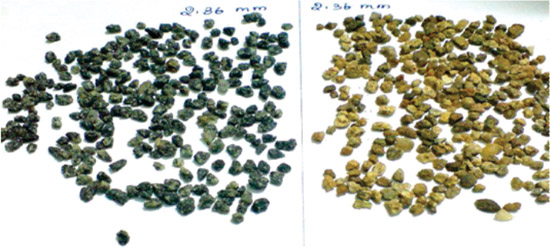

| VSI Crushed Sand -Cubical | Jaw crushed sand -Flaky |

IS Code Provisions

BIS Guidelines IS: 383-1970 for selection and testing of Coarse and Fine aggregates available. Generally, Sand is classified as Zone I, Zone II, Zone III and Zone IV (i.e. Coarser to Finer). There is sieve designation for each zone. Gradation is made in accord with the usage of the sand. There are testing sieves, consists of 4.75mm, 2.36mm, 1.183mm, 600microns, 300 microns, 150 microns and a pan

| Typical Sieve analysis: Comparison of River & Manufactured Sand | |||

| IS Sieve | % of passing(River Sand) | % of passing (Manufactured Sand ) | Zone II (As per IS:383) |

| 4.75mm | 100 | 100 | 90-100 |

| 2.36mm | 99.7 | 90.7 | 75-100 |

| 1.18mm | 89 | 66.2 | 55-90 |

| 600micron | 60.9 | 39.8 | 35-59 |

| 300micron | 17.7 | 25.5 | 8-30 |

| 150micron | 3.1 | 9.9 | 0-20 |

| 75micron | Max 3 | Max 15 | Max 15 |

| Zone II | Zone II | ||

| Zone IIZone IINote: The gradation of manufactured sand can be controlled at crushing plant | |||

| Technical specification – comparison between Manufactured and River sand | ||||

| Sl No | Property | River sand | Manufactured sand | Remarks |

| 1 | Shape | Spherical particle | Cubical particle | Good |

| 2 | Gradation | Cannot be controlled | Can be controlled | |

| 3 | Particle passing 75micron | Presence of silt shall be less than 3%(IS:383-1970)reaffirmed 2007 | Presence of dust particle shall be less than 15% | Limit 3% for uncrushed & limit 15% for crushed sand |

| 4 | Silt and Organic impurities | Present (Retard the setting & Compressive Strength) | Absent | Limit of 5% for Uncrushed & 2% for Crushed sand |

| 5 | Specific gravity | 2.3 – 2.7 | 2.5 – 2.9 | May vary |

| 6 | Water absorption | 1.5 - 3% | 2 – 4% | Limit 2% |

| 7 | Ability to hold surface moisture | Up-to 7% | Up-to 10% | |

| 8 | Grading zone(FM) | Zone II and III FM 2.2 -2.8 | Zone II FM 2.6 – 3.0 | Recommends Zone II for Mass Concrete |

| 9 | Soundness(Sodium sulphate-ss & Magnesium sulphate -ms) (5 cycles) | Relatively less sound (Ex. >5) | Relatively sound (Ex. <5) | Limit 10% ss and 15% ms |

| 10 | Alkali Silica Reactivity | 0.002 -0.01 | 0.001- 0.008 | Limit 0.1%expansio |

| Behaviour of Manufactured & River Sand when used in Concrete: | ||||

| Sl No | Property | River sand | Manufactured sand | Remedies |

| 1 | Workability & its retention | Good & Good retention | Less & Less retention | Control of fines & apply water absorption correction, use of plasticisers |

| 2 | Setting | Normal | Comparatively faster | Apply water absorption correction, use retarders |

| 3 | Compressive strength | Normal | Marginally higher | As shown above |

| 4 | Permeability | Poor | Very poor | |

| 5 | Cracks | Nil | Tend to surface crack | Early curing & protection of fresh concrete |

| Cost comparison of Manufactured and River sand: | ||||

| Sl no | Location- Bangalore City | River sand | Artificial sand | Remarks |

| 1 | Market rate | Rs 1100 per MT | Rs 600 per MT | 50% Cheaper |

| 2 | In Concrete - Rs per Cum | Rs 770 – 880 | Rs 420 – 480 | Saving of Rs 350-400 per cum |

| 3 | In Mortar(1:5) for 100kgs | Rs 198 | Rs 156 | 20% less |

Typical Compressive Strength of Concrete: The following results show the behavior of manufactured sand and riverbed sand when used in concrete:

- With using Riverbed Sand: (All proportions are by weight)

- Cement -50 Kg

- River Sand -75 Kg

- Agg. 20 mm- 75 Kg

- Agg. 12 mm -37.5 Kg

- Water -19 ltrs

- With using Artificial Sand : (All proportion are by weight)

- Cement -50 Kg

- Artificial Sand - 70 Kg

- Agg. 20 mm - 80 Kg

- Agg. 12 mm - 35 Kg

- Water - 19 ltrs

Now-a-days, Vastu Shastra is more popular, consults Vastu by many people while constructing a house. As per Vastu Shastra, the building material must be free from traces of human or animal body. The river sand contains bones of human beings and animals. The shells are also a kind of bone. It is not easy to take out all such things present in the river sand. Hence, the best solution for this is to use artificial/crushed sand of good quality for human well being.

Environmental Impact

The River sand lifting from river bed, impact the environment in many ways:

- Due to digging of the sand from river bed reduces the water head, so less percolation of rain water in ground, which result in lower ground water level.

- The roots of the tree may not be able to get water.

- The rainwater flowing in the river contents more impurities.

- Erosion of nearby land due to excess sand lifting

- Disturbance due to digging for sand & lifting, Destroys the flora & fauna in surrounding areas

- The connecting village roads will get badly damaged due to over- loading of trucks, hence, roads become problem to road users and also become accidents prone

- Diminishing of Natural Rivers or river beds, not available for future generations.

- Considering, the acute shortage of river sand, huge short coming on quality of river sand, high cost, greater impact on road damages and environmental effects, The Construction Industry shall start using the manufactured sand to full extent as alternative, reduce the impacts on environment by not using the river sand.

- The Local Authorities/PWD/ Govt, shall encourage the use of Manufactured sand in Public Construction Works, if possible, shall make mandatory to use Manufactured sand wherever available with immediate effect.

- The Govt. Shall come out with, Policy on Sand – encourage the industry people to set up more no of Sand crushing Units across the all Districts, States to meet the sand requirements of the Construction Industry.

www.vsicrushers.com

www.robosilicon.com