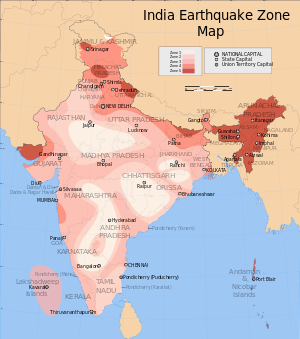

Earthquake zones of India

Press data Bureau

Government of India

Ministry of natural science

Earthquake Prone Zone

Bureau of Indian Standards, supported the past unstable history, classified the country into four unstable zones, viz. Zone-II, -III, -IV and –V. Of these, Zone V is that the most seismically active region, whereas zone II is that the least. The changed Mercalli (MM) intensity, that measures the impact of the planetquakes on the surface of the earth, broadly speaking related to varied zones, is as follows:

Seismic Zone Intensity on millimetre scale

II (Low intensity zone) VI (or less)

III (Moderate intensity zone) VII

IV (Severe intensity zone) VIII

V (Very severe intensity zone) IX (and above)

Broadly, Zone-V contains of entire northeastern Asian nation, components of Jammu and geographical region, Himachal Pradesh, Uttaranchal, Rann of tannic acid in Gujarat, components of North Bihar and Andaman & Nicobar Islands. Zone-IV covers remaining components of Jammu & geographical region and Himachal Pradesh, Union Territory of metropolis, Sikkim, northern components of province, Bihar and West Bengal, components of Gujarat and little parts of geographic area close to the geographical area and Rajasthan. Zone-III contains of Kerala, Goa, Lakshadweep islands, and remaining components of province, Gujarat and West Bengal, components of geographic region, Rajasthan, Madhya Pradesh, Bihar, Jharkhand, Chhattisgarh, geographic area, Orissa, province, Tamilnadu and Karnataka. Zone-II covers remaining components of the country.

Further, as a part of pre-disaster readiness live, Government of Asian nation has additionally completed unstable microzonation studies of a number of the most important cities within the country like, Jabalpur, Guwahati, Bangalore, larger Bharuch in Gujarat, Jammu in J & K, Shillong in Meghalaya, city in Tamilnadu and geographical region state. These studies involving preparation of geologic, morphologic and land use maps followed by drilling, geologic work, normal penetration take a look at and geology studies to demarcate the zones of least to most harm prone areas at intervals the urban areas helps the individual city and country coming up with agencies to formulate perspective coming up with at intervals the earthquake impact minimisation efforts.

This info was given by Minister of Earth Sciences Dr. Harsh Vardhan in Lok Sabha nowadays.

KSP/SRD

The Indian subcontinent has a history of devastating earthquakes. The major reason for the high frequency and intensity of the earthquakes is that the Indian plate is driving into Asia at a rate of approximately 47 mm/year.[1] Geographical statistics of India show that almost 54% of the land is vulnerable to earthquakes. A World Bank and United Nations report shows estimates that around 200 million city dwellers in India will be exposed to storms and earthquakes by 2050.[2] The latest version of seismic zoning map of India given in the earthquake resistant design code of India [IS 1893 (Part 1) 2002] assigns four levels of seismicity for India in terms of zone factors. In other words, the earthquake zoning map of India divides India into 4 seismic zones (Zone 2, 3, 4 and 5) unlike its previous version, which consisted of five or six zones for the country. According to the present zoning map, Zone 5 expects the highest level of seismicity whereas Zone 2 is associated with the lowest level of seismicity.

Press data Bureau

Government of India

Ministry of natural science

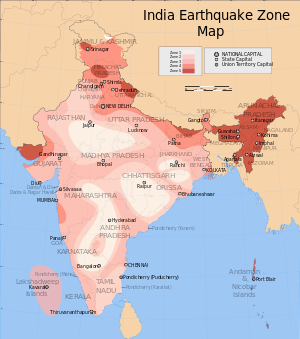

Earthquake Prone Zone

Bureau of Indian Standards, supported the past unstable history, classified the country into four unstable zones, viz. Zone-II, -III, -IV and –V. Of these, Zone V is that the most seismically active region, whereas zone II is that the least. The changed Mercalli (MM) intensity, that measures the impact of the planetquakes on the surface of the earth, broadly speaking related to varied zones, is as follows:

Seismic Zone Intensity on millimetre scale

II (Low intensity zone) VI (or less)

III (Moderate intensity zone) VII

IV (Severe intensity zone) VIII

V (Very severe intensity zone) IX (and above)

Broadly, Zone-V contains of entire northeastern Asian nation, components of Jammu and geographical region, Himachal Pradesh, Uttaranchal, Rann of tannic acid in Gujarat, components of North Bihar and Andaman & Nicobar Islands. Zone-IV covers remaining components of Jammu & geographical region and Himachal Pradesh, Union Territory of metropolis, Sikkim, northern components of province, Bihar and West Bengal, components of Gujarat and little parts of geographic area close to the geographical area and Rajasthan. Zone-III contains of Kerala, Goa, Lakshadweep islands, and remaining components of province, Gujarat and West Bengal, components of geographic region, Rajasthan, Madhya Pradesh, Bihar, Jharkhand, Chhattisgarh, geographic area, Orissa, province, Tamilnadu and Karnataka. Zone-II covers remaining components of the country.

Further, as a part of pre-disaster readiness live, Government of Asian nation has additionally completed unstable microzonation studies of a number of the most important cities within the country like, Jabalpur, Guwahati, Bangalore, larger Bharuch in Gujarat, Jammu in J & K, Shillong in Meghalaya, city in Tamilnadu and geographical region state. These studies involving preparation of geologic, morphologic and land use maps followed by drilling, geologic work, normal penetration take a look at and geology studies to demarcate the zones of least to most harm prone areas at intervals the urban areas helps the individual city and country coming up with agencies to formulate perspective coming up with at intervals the earthquake impact minimisation efforts.

This info was given by Minister of Earth Sciences Dr. Harsh Vardhan in Lok Sabha nowadays.

KSP/SRD

The Indian subcontinent has a history of devastating earthquakes. The major reason for the high frequency and intensity of the earthquakes is that the Indian plate is driving into Asia at a rate of approximately 47 mm/year.[1] Geographical statistics of India show that almost 54% of the land is vulnerable to earthquakes. A World Bank and United Nations report shows estimates that around 200 million city dwellers in India will be exposed to storms and earthquakes by 2050.[2] The latest version of seismic zoning map of India given in the earthquake resistant design code of India [IS 1893 (Part 1) 2002] assigns four levels of seismicity for India in terms of zone factors. In other words, the earthquake zoning map of India divides India into 4 seismic zones (Zone 2, 3, 4 and 5) unlike its previous version, which consisted of five or six zones for the country. According to the present zoning map, Zone 5 expects the highest level of seismicity whereas Zone 2 is associated with the lowest level of seismicity.

Center for Seismology

Center for geophysics, Ministry of Earth Sciences is nodal agency of state of India handling numerous activities within the field of geophysics and allied disciplines. the foremost activities presently being pursued by the middle for geophysics embrace, a) earthquake watching on 24X7 basis, as well as real time unstable watching for early warning of tsunamis, b) Operation and maintenance of national seismologic network and native networks c) seismologic information centre and data services, d) unstable hazard and risk connected studies e) Field studies for earth tremor / swarm watching, website response studies f) earthquake processes and modelling, etc.[3] The MSK (Medvedev-Sponheuer-Karnik) intensity loosely related to the varied unstable zones is VI (or less), VII, VIII and IX (and above) for Zones two, 3, 4 and 5, severally, resembling most thought of Earthquake (MCE). The IS code follows a twin style philosophy: (a) underneath low likelihood or extreme earthquake events (MCE) the structure injury shouldn't end in total collapse, and (b) underneath additional oft occurring earthquake events, the structure ought to suffer solely minor or moderate structural injury. The specifications given within the style code (IS 1893: 2002) don't seem to be supported elaborate assessment of most ground acceleration in every zone employing a settled or probabilistic approach. Instead, every zone issue represents the effective amount peak ground accelerations that will be generated throughout the utmost thought of earthquake ground motion therein zone.

Each zone indicates the consequences of associate degree earthquake at a specific place supported the observations of the affected areas and might even be delineated employing a descriptive scale like changed Mercalli intensity scale[4] or the Medvedev–Sponheuer–Karnik scale.[5]

Zone 5

Zone five covers the areas with the best risks zone that suffers earthquakes of intensity MSK IX or larger. The IS code assigns zone issue of zero.36 for Zone five. Structural styleers use this issue for earthquake resistant design of structures in Zone five. The zone issue of zero.36 is indicative of effective (zero period) level earthquake during this zone. it's named because the terribly High harm Risk Zone. The region of Jammu and Kashmir, the Western and Central chain of mountains, North and Middle province, the North-East Indian region, the Rann of tannin and therefore the Andaman and Nicobar cluster of islands fall during this zone.

Generally, the aras having lure rock or volcanic rock rock are susceptible to earthquakes.

Zone 4

This zone is termed the High injury Risk Zone and covers areas vulnerable to MSK VIII. The IS code assigns zone issue of zero.24 for Zone four Jammu and geographic area, Himachal Pradesh, Uttarakhand, Sikkim, the components of Indo-Gangetic plains (North geographic region, Chandigarh, Western Uttar Pradesh, Terai, North geographical region, Sundarbans) and therefore the capital of the country Delhi fall in Zone four. In Maharashtra, the Patan space (Koynanagar) is additionally in zone no-4. In Bihar the northern a part of the state like Raxaul, close to the border of Asian nation and Nepal, is additionally in zone no-4.

Zone 3

This zone is classified as Moderate Damage Risk Zone which is liable to MSK VII. and also 7.8 The IS code assigns zone factor of 0.16 for Zone 3.

Zone 2

This region is liable to MSK VI or less and is classified as the Low Damage Risk Zone. The IS code assigns zone factor of 0.10 (maximum horizontal acceleration that can be experienced by a structure in this zone is 10% of gravitational acceleration) for Zone 2.

Zone 1

Since the current division of India into earthquake hazard zones does not use Zone 1, no area of India is classed as Zone 1.

Future changes in the classification system may or may not return this zone to use.