Step by step method to Construct RC Residential House in India

Many houses are constructed as a framed structure because of its strength, faster construction, and feasibility for future modification and extension. In this article, we are going to discuss how to construct an RCC residential house in India. This will be very useful for entry-level engineers to understand the different processes and steps involved in the construction of the house in India.

Needs and specifications

First, the client will approach the engineer and provide the needs and expectations he/she wants in the building. Then the engineer will suggest ideas and discuss possibilities to bring the needs of the client to reality.

After deciding the type of the house, built-up area, no of rooms, and other utilities, the engineer will give a rough estimate of the cost and time of completion of the project.

Site Visit

- The engineer and Client will visit the site to study the site.

- Site clearance will be performed to remove the stones, plants, etc..,

- The site will be leveled and compacted. Now the site is ready for construction.

Preparation of Plan to construct a house in India

- Engineer (or architect) will prepare the best plan to construct a house in India which fulfills the client's needs.

- The engineer will decide the specifications.

- A “plan blueprint” will be created and sent to the local government body like the panchayat union, municipality, or corporation for getting approval. Blueprint plan will contain Plan, section and elevation of the house along with site plan, septic tank details, area details, sizes of items like doors, windows and ventilators and area details like plot area, built-up area, etc..,

Also Read: How to get a building permit in India? – Required Documents, Plans and application fees

Transfer of loads in Framed building

Slabs and floors transfer the like furniture and others to the beams which in turn transfer the load to the columns. Columns will carry the total load of the structure to the footings and finally, through footings load will be distributed to the soil. In a framed structure, walls only carry the self-weight. The load from the beam will not be transferred to walls.

Design of Building

- The engineer will prepare the structural design of the building by following design procedures, National Building code(NBC), and IS456 codebook. Many experienced engineers use empirical methods for design if the building is small.

- Sizes of the different members like beams, columns, depth of foundation, the thickness of floors, etc.., will be designed.

- Reinforcement details like the number of bars, size of bars, and spacing of bars will be designed. Reinforcement design is very important because the improper design could result in collapse or increase the cost of the building.

- Then, the Plumping plan and the electrical plan will be prepared. Preparing plumping and electrical plans prior to construction of the building will save a lot of time and money.

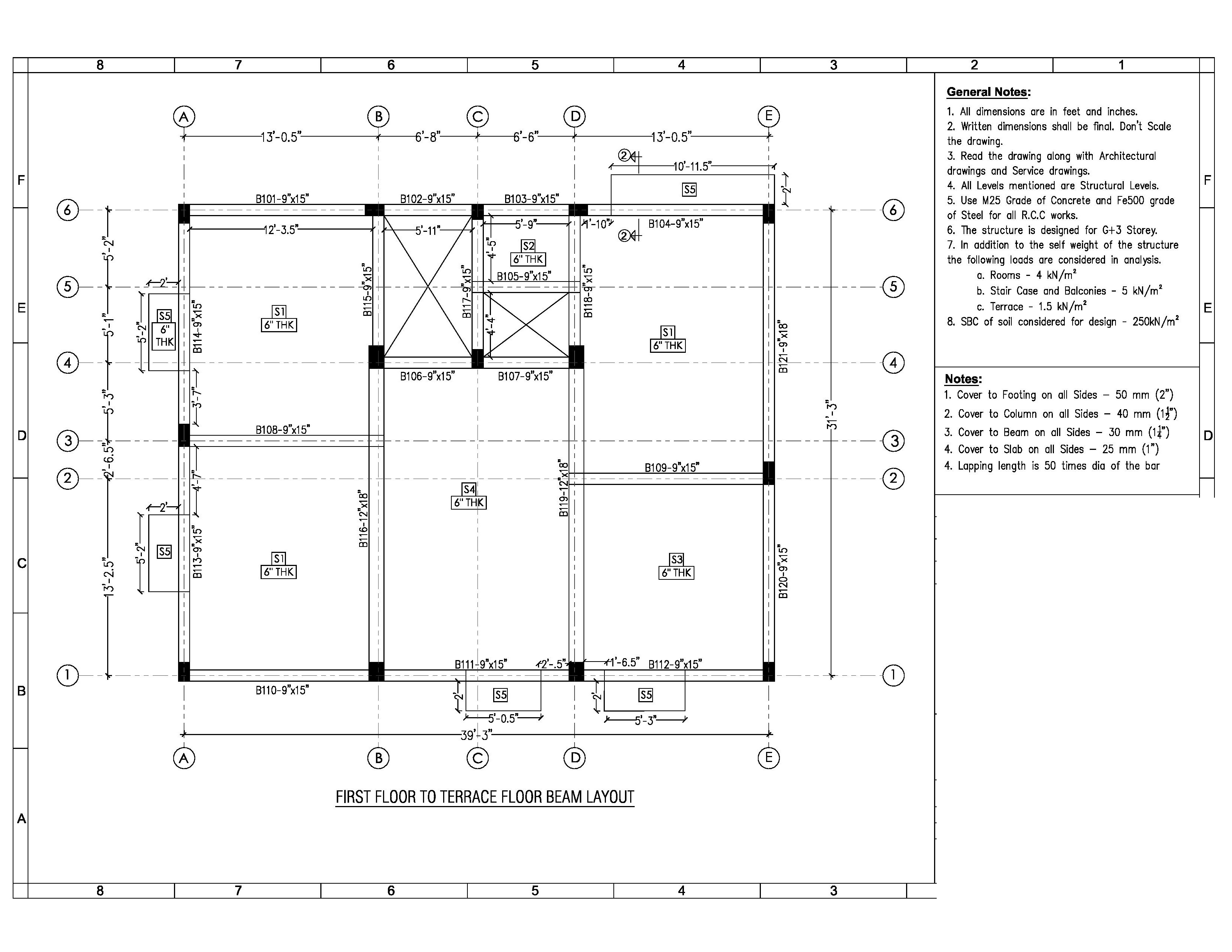

SAMPLE STRUCTURAL BEAM LAYOUT – CLICK ON THE IMAGE TO GET A BETTER VIEW

Construction of foundation

- Engineers will mark the places to be excavated for column footings, grade beams (column belt) with threads, white powder, and pegs.

- The minimum depth of the column foundation is 5 feet (1.5m), and the Minimum footing dimension is 3 feet length (1m) and 3 feet breadth.

- After excavation, sand will be filled for at least 6 inches, and plain cement concrete PCC in the ratio of 1:5:10 will be provided for at least 6 inches.

- Above the PCC concrete mat, column reinforcement will be fixed with the help of wooden posts.

- Footing will be cast around the reinforcement

- The column will be cast around the column reinforcement up to the grade beam level (column belt).

Construction of Grade Beam and Column

- A grade beam will be constructed on the ground level which will connect all columns and act as a column belt.

- The thickness of the grade beam is usually 9 inches to support the wall and the depth is usually 9 inches or 1 ft.

- The column shows will be cast and the column will be constructed up to the beam bottom level.

Construction of Wall

- Main walls with a thickness of 9 inches will be constructed above the grade beam as per plan.

- Provisions for windows, doors, ventilators, etc., will be given in the form of opening will be provided in the walls.

- Walls will be constructed up to the beam bottom level with 6 inches gab to avoid the transfer of a load of the beam to the wall.

- The parapet wall will be constructed over the roof for a minimum height of 1m for smaller buildings and 1.6m for taller buildings.

Construction of Beam and Slab

- Shuttering/Centering will be constructed with the help of Planks and posts.

- Since beams and slabs are cast on the shuttering they should be the inexact size as per plan.

- Required steel rebar will be bought and cut to the required shape and bend to the required shape by bar bender as per the bar bending schedule.

- Steel reinforcement will be placed over the shuttering.

- Provisions for electrical conduit and pipe conduit will be provided.

- Steel reinforcement will be thoroughly checked for the size, spacing, fixing, cover spacing, etc.., by professional

- Concrete of appropriate grade will be poured over the shuttering and slab and a beam will be cast.

Construction of Floor

- For the Ground floor, Sand will be filled up to the required height.

- PCC will provide usually with a thickness of 3 inches above the consolidated sand/earth.

- Concrete flooring with a thickness of 1 inch or tile flooring will be proved above PCC before painting.

- For Roof flooring, PCC jelly with waterproof materials will be provided to avoid the seepage of water into the building

- Roofing tiles will be provided over the roof.

Painting, Doors, Windows, Electrical Conduits, Plumbing, and sanitary fixings

- Doors and windows will be fixed before the painting

- Piping will be fixed before the tilling

- Sanitary fixers will be fixed after painting

- Interior painting and exterior painting will be done after all important works

- Wiring will be provided

- Electrical equipment, furniture and the like will be provided

Quality metal buildings will retain their original beauty and value outstandingly well.

ReplyDelete4 Trends for Prefab Steel Construction That You will Love