Design problems are seldom amenable to solution by exact mathematical formulae.

There is a considerable scope for exercising engineering judgement. Hence, there is no

“correct solution” to a design problem, as there could be several so-called “correct solutions”

to the same problem. This is because

• the designs are invariably subject to individual interpretation of Standards and Codes,

• the solutions are also subject to differing ideas about what is or what is NOT required from

an engineering and environmental stand point, and

• the individual designers have ingrained ideas from their past experience, which may be

valid to-day only to a limited extent, or may not be valid at all.

Thus the design problems are referred to as "open ended" problems. Nevertheless the

Designer has the responsibility for ensuring that the goal of the project is achieved (i) safely,

without taking any undue risks to lives and materials and without causing a liability, (ii)

within time and (iii) within the (budgeted) cost. Hence, “Engineering Design” may be defined

as a creative activity of building a new artefact which provides an optimum solution to satisfy

a defined requirement or need, without endangering the environment.

Traditionally the professional Structural Engineer had invariably played a vital role in the

design of constructed facilities, often, in close association with other professionals like

Architects and others in related disciplines. As a designer, he is responsible for the complete

process from the conceptual stages to the finished structure. Increasingly, the Society expects

him to assume responsibility for the durability of the product. In other words, the

responsibility of a professional Structural Engineer in the 21st century will not be confined

merely to the immediate economic and environmental impact of his design decisions; society

expects him to make rational and responsible choices by considering the life cycle costs and

the long-term environmental effects on the community In the following pages, we will

highlight the enhanced role of the Professional Engineer in the 21st century and explore how

the two design criteria are interlinked.

The Construction Industry, with all its imperfections and limitations, is rightly perceived

as the provider of the Nation’s infrastructure. Clearly, it is of paramount importance to train

and educate those who create and manage it, in order to ensure the economic and

environmental survival of the world. While the world has witnessed some fantastic advances

in Science and Technology in recent years, many of these achievements have been made at an

outrageous price, plunging the world into a number of crises, which have impacted directly

on the construction industry. The global effect of these dramatic changes in the world in the

last 50 years can be collectively termed the “infrastructure crisis”, which has to be

encountered and managed by the construction industry.

Issues of durability have always been subjects of debates among Engineers. Is it better to

spend (say) 40% more initially, in order that the life of a structure could be doubled? What is

better value to the client? Spend less initially or opt for a longer life? Total neglect of

durability considerations in all the infrastructure projects undertaken so far combined with

primitive construction practices still prevailing in India have resulted in what can only be

termed a “durability crisis”. It is now well established that degradation of all structures has

become very common in almost all the cities in India and this is particularly true of buildings

and structures made of reinforced/prestressed concrete. The great tragedy is that there have

been no efforts to address this issue by the present generation of Developers, Engineers,

Architects and other design professionals. As a consequence, major problems have been

allowed to accumulate for future generations of owners and taxpayers to face.

When a constructed facility is completed, it will be put to use immediately and this results

in a return on the capital employed. Delays in the completion of a project would therefore

represent a delay in the return on capital invested, besides the loss of interest, which that sum

would have earned otherwise. This essential relationship between time and money is well

understood in the present context.

Unfortunately for the Indian client, many architects and designers seldom consider the use

of alternative materials of construction and the designs are invariably limited to “concreteintensive” structures. Often the best optimal design solution is obtained by a sensible

combination of reinforced and/or prestressed concrete elements with structural steel elements.

Even when a “steel-intensive” solution is selected; it is very rare for limiting the selection of

materials of construction to steel only.

Although India has an installed capacity to produce 35 million tonnes of steel/year, we

manage to produce only 24 million tonnes/year of which the use in the construction sector

accounts for around 25% - 30%. By way of comparison, China produced 120 million tonnes

of steel during 1999 - 2000 and Japan, 95 million tonnes. The total per capita consumption of

steel in all its forms in India is one of the lowest in the world, being 24 kg/annum, compared

with 500 kg/annum in the USA and 700 kg/annum in Japan. According to the recent research

by the Steel Construction Institute, there is a direct link between the gross national product

per capita and the per capita consumption of steel.

Indeed, structural steel has inherently superior characteristics to a very significant extent,

when compared with competing materials. For example, to replace one unit area of steel in

tension, (with a yield stress of 450 MPa), we would need to use an equivalent plain concrete

area of about 200 units. For concrete to be able to compete with Structural Steel in

construction, we need to put Reinforcing Steel into it! Even then, there is no way to prevent

the cracking of concrete in tension, which often encourages corrosion of reinforcement. In

compression (or squash loading), one unit area of steel is the equivalent of 15-20 units of

M20 concrete. A comparison of strength/weight ratio will reveal that steel is at least 3.5 times

more efficient than concrete. For a given compressive loading, concrete would have 8 times

the shortening of steel. Again we need reinforcing steel to prop up the plain concrete.

In structures built of Structural Steel, occasional human errors (like accidental

overloading) do not usually cause any great havoc, as there is a considerable reserve strength

and ductility. Steel may thus be regarded as a forgiving material whereas concrete structures

under accidental overload may well suffer catastrophic collapse of the whole structure.

Repair and retrofit of steel members and their strengthening at a future date (for example, to

take account of enhanced loading) is a lot simpler than that of reinforced concrete members.

The quality of steel-intensive construction is invariably superior, when compared with all

other competing systems (including concrete structures) thus ensuring enhanced durability.

This is especially true in India, where quality control in construction at site is poor.

Structural Steel is recyclable and environment-friendly. Over 400 million tonnes of steel

infrastructure and technology for the recycling of steel is very well established. Steel is the

world's most versatile material to recycle. But once recycled, steel can hop from one product

to another without losing its quality. Steel from cans, for instance, can as easily turn up in

precision blades for turbines or super strong suspension cables. Recycling of steel saves

energy and primary resources and reduces waste. A characteristic of steel buildings is that

they can readily be designed to facilitate disassembly or deconstruction at the end of their

useful lives. This has many environmental and economic advantages; it can mean that steel

components can be re-used in future buildings without the need for recycling, and the

consequent avoidance of the energy used and CO2 emitted from the steel production

processes.

Steel-intensive construction causes the least disturbance to the community in which the

structure is located. Fast-track construction techniques developed in recent years using steel-intensive solutions have been demonstrated to cause the least disruption to traffic and

minimize financial losses to the community and business. Even though “the initial cost” of a

concrete intensive structure may sometimes appear to be cheaper, compared to the equivalent

steel-intensive structure, it has been proved time and again that its total lifetime cost is

significantly higher. Thus the popular perception of the concrete-intensive structure being

cheaper is NOT based on verifiable facts! There is therefore no real cost advantage either.

Except in a few special structures like tower cranes and transmission towers, it is rare to

build a structure entirely in steel. Frequently the optimal solution is obtained by employing

concrete elements compositely with structural steel, especially in multi-storeyed buildings

and bridges. These methods ensure significant cost benefits to the developers (or owners of the property) as well as to the community. Composite structural forms have been extensively

developed in the western world to maximize the respective benefits of using structural steel

and concrete in combination, but this technology is largely ignored in India, despite its

obvious benefits. The sizes of composite beams and columns will be appreciably smaller and

lighter than that of the corresponding reinforced or prestressed sections for resisting the same

load. A direct economy in the tonnage of steel and indirect economies due to a decrease in

construction depths of the floors and reduced foundation costs will, therefore, be achieved.

Generally, improvements in the strengths of the order of 30% can be expected by mobilizing the

composite action. An independent study carried out by the Central Building Research

Institute (CBRI) Roorkee demonstrated that there are substantial cost savings to be achieved

by the use of Composite Construction

A structural engineer’s responsibility is to design the structural systems of buildings,

bridges, dams, offshore platforms, etc. A system is an assemblage of components with

specific objectives and goals and subject to certain constraints or restrictions. System components are required to co-exist and function in harmony, with each component meeting

a specific performance. Systems design is the application of a scientific method to the

selection and assembly of components to form the optimum system, to achieve the specified

goals and objectives, while satisfying the given constraints or restrictions.

In practice, any constructed facility can be considered as a “System”. The Structural

System is one of its major subsystems and is indeed its backbone. Some of the other

coexisting subsystems are those connected with the mechanical, electrical, plumbing and

lighting facilities. Structural components have to meet the design requirements of adequate

strength under extreme loads and required stiffness under day-to-day service loads while

satisfying the criteria of economy, buildability, and durability.

Examples of civil engineering systems include buildings, bridges, airports, railroads,

tunnels, water supply networks, etc. For example, a building system is an assemblage

constructed to provide shelter for human activities or enclosure for stored materials. It is

subject to restrictions by building specifications on height, floor area, etc. Constraints include the ability to withstand loads from human activities and from natural forces like wind and

earthquakes. As pointed above, a system consists of many subsystems, i.e. components of the

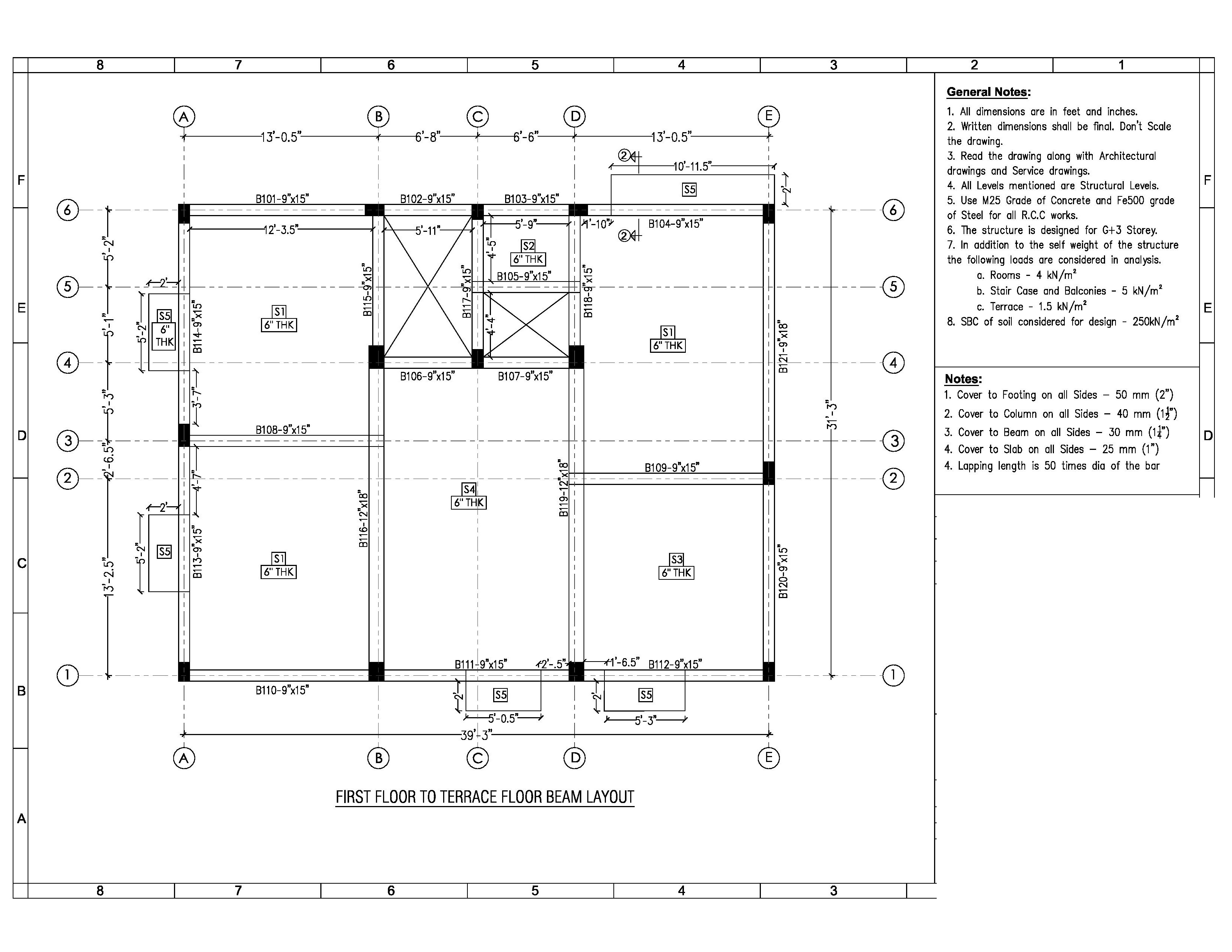

system. For example, in a building, major subsystems are structural framing, foundations,

cladding, non-structural walls, and plumbing. Each of these subsystems consists of several

interrelated components. In the case of structural framing, the components include columns,

beams, bracing, connections, etc. The richness and variety of structural systems can be

appreciated by the available building structural types that range from massive building blocks

to shell structures, from structures above or below ground or in water, to structures in outer

space. Examples of a few steel-framed structures.

Thnaks to

Prof. Ajaya Kumar Nayak,

Er.SP.ASWINPALANIAPPAN., M.E.,(Strut/.,)

Structural Engineer