Calculate Sand & Gravel per 50kg Cement Bag in Volume & Weight

Proper batching of cement, fine aggregate(sand) and coarse aggregate(gravel or jalli) are important to get a good quality of concrete. This article will show you how to calculate sand and gravel needed per bag of cement (50kg) to prepare concrete as per the codebook.

Let’s first understand the role of different ingredients in making concrete. Cement is the active ingredient that binds the inactive ingredients and gives strength to concrete, whereas aggregates like sand and gravel act as filler materials to reduce the usage of cement and decrease the shrinkage in concrete.

Based on strength, concrete is classified into different grades like M5, M7.5, M10, M15, M20, etc.. Number in the grade denotes the strength of the concrete is 28 days. We can achieve targeted strength by using proper quantities of materials to prepare concrete.

Weight of Sand and Gravel (Jalli) needed for 1 bag of Cement

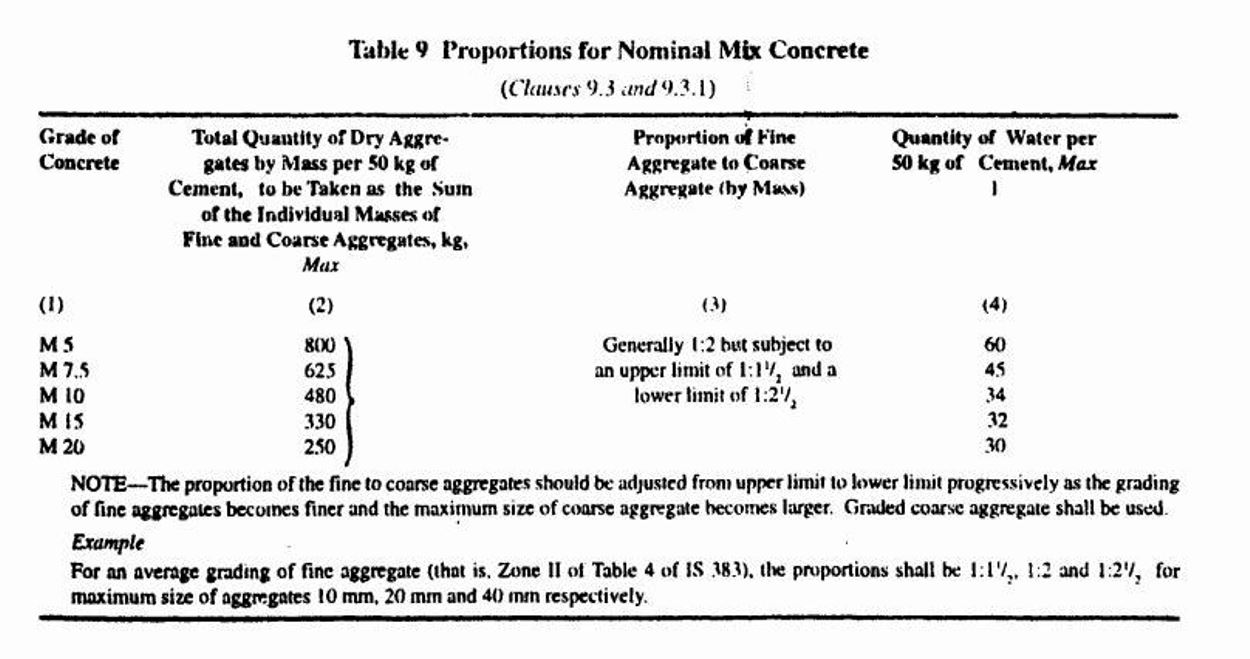

Calculating ingredients in terms of weight is called weigh batching. They are used in places like ready mix plant and laboratories to get accurate results. Codebook suggests the following total aggregates (sand + gravel) per 50kg bag of cement. It does not give separate values for sand and gravel so we have to find them on our own.

| CONCRETE GRADE | CEMENT (BAGS) | TOTAL AGGREGATES (SAND + GRAVEL) |

| M5 | 1 | 800 kg |

| M7.5 | 1 | 625 kg |

| M10 | 1 | 480 kg |

| M15 | 1 | 330 kg |

| M20 | 1 | 250 kg |

The ratio of fine aggregate to coarse aggregate to be used in concrete is 1:2, which means that for every 1 part of sand we have to take 2 parts of gravel. Hence we have to divide the Total Aggregate into 3 parts and take 1 part as sand and 2 parts as coarse aggregate.

Let's calculate the weight of sand and gravel needed for M15 Grade concrete.

Weight of Sand required per bag of cement = (330/3) x 1 = 110 kg

Weight of gravel required per bag of cement = (330/3) x 2 = 220 kg

Therefore to prepare M15 Grade concrete, use 110 kg of sand and 220 kg of gravel per bag of cement.

Weight of sand and gravel needed per bag of cement for different concrete grades

| CONCRETE GRADE | CEMENT (BAGS) | SAND (KG) | GRAVEL (KG) |

| M5 | 1 | 265 | 535 |

| M7.5 | 1 | 210 | 415 |

| M10 | 1 | 160 | 320 |

| M15 | 1 | 110 | 220 |

| M20 | 1 | 85 | 165 |

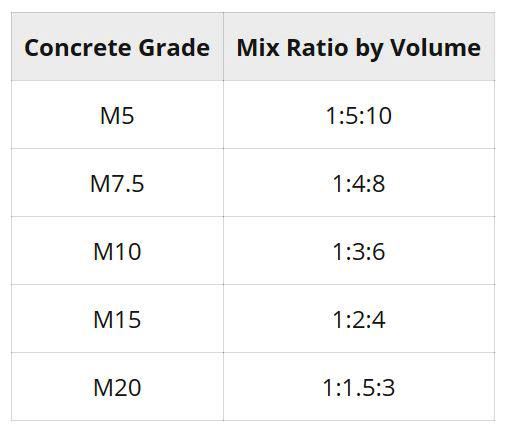

The volume of Sand and Gravel needed for 1 bag of cement in cubic feet CFT

Calculating ingredients in terms of volume is called volume batching. Volume batching is preferred for the onsite preparation of concrete. It is easy and faster than weigh batching. Codebook suggests the following volumetric mix ratio for different grades of concrete.

Let's calculate the volume of sand and gravel needed to prepare M15 grade concrete

Mix Ratio of M15 grade concrete is 1:2:4. Hence for every 1 part of cement, we have to use 2 parts of sand and 4 parts of gravel to get M15 ratio concrete. The volume of the 50 kg cement bag is 1.25 CFT. We can check this value by dividing the weight of the cement bag by the bulk density of cement. The volume of batching box used in the construction site is also 1.25 CFT.

Mix Ratio of M15 Grade concrete = 1:2:4

Volume of sand needed = Volume of cement bag x Ratio of sand

Volume of sand needed = 1.25 x 2 = 2.5 CFT

Volume of Gravel needed = 1.25 x 4 = 5 CFT

Therefore to prepare M15 Grade concrete, use 2.5 cubic feet of sand and 5 cubics of gravel per bag of cement.

The volume of sand and gravel needed per bag of cement for different concrete grades

| CONCRETE GRADE | CEMENT (BAGS) | SAND (CFT) | GRAVEL (CFT) |

| M5 | 1 | 6.25 | 12.5 |

| M7.5 | 1 | 5 | 10 |

| M10 | 1 | 3.75 | 7.5 |

| M15 | 1 | 2.5 | 5 |

| M20 | 1 | 1.88 | 3.75 |

Please note that the above quantities are only prescribed quantities and slight variations in the quantities are allowed, and even sometimes they are desirable. For example, a slight increase in the quantity of sand can save cost on cement and also increase the shrinkage resistance. But, quantities of aggregates should not be increased by more than 20% than the prescribed quantities given above. Always consult the engineer for making any changes in the quantities given above.

Liters of water needed per 50kg bag of cement

W/C ratio is not applicable for nominal mix ratio concrete. IS456 Table 9 suggests the following liters of water for M5, M7.5, M10, M15, M20 grade concrete. Normally, Engineers use the known volume of containers or buckets to measure water for concrete.

| CONCRETE GRADE | LITRES OF WATER PER 50KG CEMENT BAG |

| M5 | 60 Liters |

| M7.5 | 45 Liters |

| M10 | 34 Liters |

| M15 | 32 Liters |

| M20 | 30 Liters |

Also Read:

Cement Sand and Aggregate needed for concrete in volume and weight

http://civilbaselife.blogspot.com/2020/04/cement-sand-and-aggregate-needed-for.html

Er.SP.ASWINPALANIAPPAN., M.E.,(Strut/.,)

Structural Engineer

Madras Terrace Architectural Works